1. Features of equipment

☆ Using aluminum alloy structure, beautiful and solid without rust

☆ Computer PLC programming control, high stability, low failure rate and low noise

☆ Imported servo motor and stepper motor drive, high precision

☆ Photoelectric detection of raw materials to avoid mistakes and reduce waste

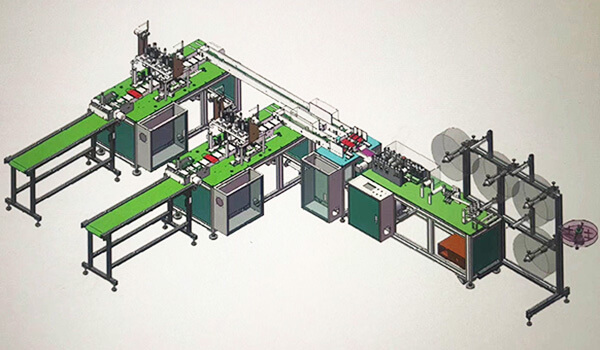

☆ One body can be connected with 1-3 inner ear straps or outer ear straps as required

☆ The machine adopts pulleys and fixed feet, which is convenient and fast to move, strong in stability, and does not shake

☆ This model is equipped with a new advanced conveyor belt, with high accuracy, no manual counting, just sorting and packing

☆ Equipment can be modified according to product requirements, product size, length and thickness

☆ Different earband machines can be configured according to different production orders, which is economical and practical

2. Equipment installation and configuration requirements

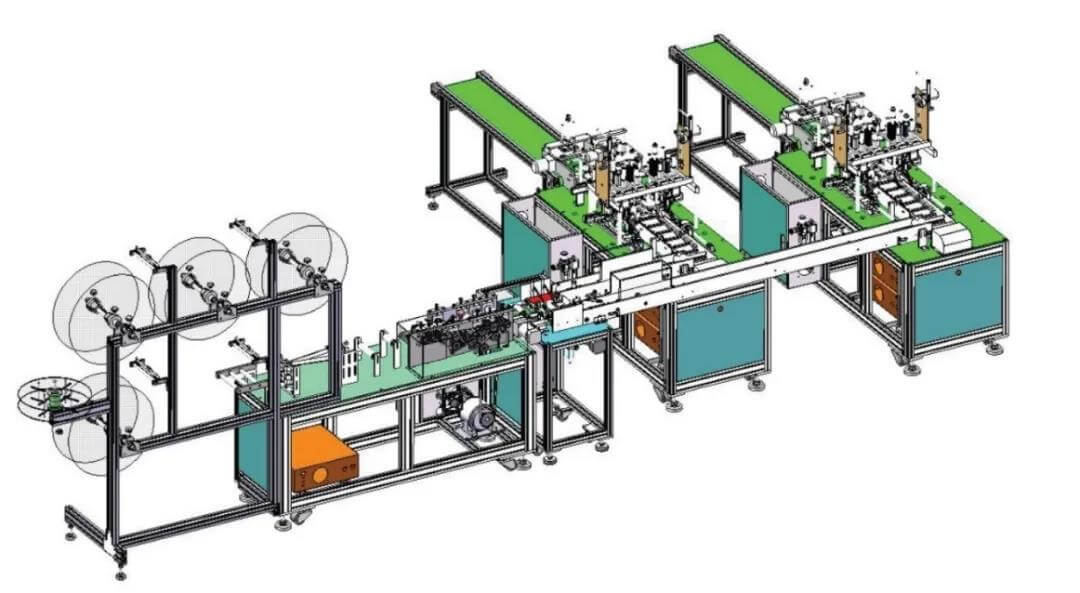

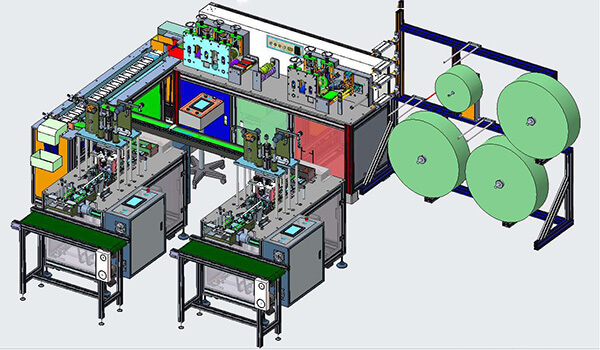

☆ Equipment size: about 7000mm (L) × 6500mm (W) × 1900mm (H)

☆ Equipment weight: ≤5000kg, ground load ≤500KG / m2

☆ Compressed air: 0.5 ~ 0.7 MPa, the use flow rate is about 300L / min

☆ Operating environment: temperature 10 ~ 35 ℃, humidity 5-35% HR, no flammable, corrosive gas, no dust (cleanness no less than 100,000)

3. Equipment production capacity:

☆ Production efficiency: 80-100ppm

☆ Qualification rate of equipment production: 99% (except that the incoming materials do not meet the requirements, or the employees' improper operation is excluded)

☆ Equipment failure rate: 2% (refers to the failure caused by the equipment itself)

4. Production specifications:

☆ Standard type: 175 × 95mm